Delivering and Deriving Value

Society and Environment

Our Approach to Local Communities

With businesses that are widespread, the impact of our activities on our stakeholders are broad-based and far reaching. The spread of our activities across the country, has resulted in our businesses being an integral part of the communities they operate in, and hence, assessment of societal requirements are part of everyday interactions at these localities.

We are mindful of our calling; to deal responsibly and fairly with the different stakeholder groups and whilst we seek to achieve our business goals, we simultaneously commit ourselves to the development and well-being, and the empowerment and enrichment of the lives of all our stakeholders whilst not compromising good ethics.

Touching lives

The enterprise of Hayleys has touched the lives of many, both directly and indirectly. Our policies on buying local, and the indirect social and economic benefits of our projects and businesses on local communities in which we operate were discussed earlier. Regarding the latter, of special note are our Firstlight programme, housing programme for plantation workers and our out-grower business model.

Integrity and Business Ethics

Our long-standing commitment to doing business with integrity and transparency, a key element in our corporate values, means avoiding corruption in any form. We conduct periodic audits of all our business operations to detect potential misconduct and monitor compliance with anti-corruption laws and relevant policies. In this context strict disciplinary action was taken on three employees in the Transportation & Logistics sector for incidents of corruption.

The Group’s Legal services has not been informed of or has pursued any action where any fines were imposed in relation to non-compliance with laws and regulations related to corruption and related matters.

Caring for Our Environment

Our management approach is two pronged: one is to design and manufacture products that do not harm the environment, and second, to minimise the impact of our own activities. Whilst generating a superior return to investors lies at the core of business, we are mindful that sustainable profit does not happen in isolation of our People and Planet.

We take pride in our diverse array of eco-friendly products and services, ranging from activated carbon, coir fibre pith, horticulture products, and our in-house R&D which has pioneered many turnkey solutions for the purification of gases, air and liquids.

Apart from manufacturing, we also represent leading global brands in agriculture, consumer products, industrial solutions, leisure & aviation and transportation & logistics. Our choice of the most appropriate principal is not based merely on how commercially attractive the liaison would be, but also on compatibility with eco-friendly principles.

We invest in best practices for the efficient use of resources such as energy, water and materials. We are actively pursuing renewable energy sources, both for internal use as well as to augment the national grid. We control the discharge of emissions, effluents and waste, whilst managing the environmental impact of their disposal.

Hayleys Commences Wind Power Generation at Nirmalapura

Nirmalapura Wind Power (Pvt) Ltd. commenced commercial operations on the 9th of August 2012, and is expected to add 10 MW to the National Grid through its wind turbine generators. The venture is the latest step towards boosting the power requirements of the nation through renewable and sustainable ‘green’ energy.

Hayleys and consortium partner, Windforce Pvt Ltd. were instrumental in providing the capital and technology necessary to build this wind power plant. The 10 MW wind plant will contribute to supporting the nation’s power generation requirements and address the demands of the future today.

Wind power is widely recognised as Sri Lanka’s best natural resource after hydro power, due to the country’s substantial monsoon winds. The farm of wind turbine generators has seven turbines, each producing 1.5 MW of power.

Power plants currently operated by Hayleys provide 5.5 MW of energy to the National Grid. The Group also provides complete turnkey solutions, develops and construct power houses, and supplies turbine generators for renewable power projects which currently supply the National Grid with a total of 9.5 MW. Further, Recogen, a Hayleys Group Company operates the world’s only pollution-free charcoaling plant, which generates electricity from waste heat, contributing towards reducing fossil fuel driven power generation-an initiative that earned the Company rights to trade-in carbon credits under the Kyoto Protocol.

Materials Usage

We are committed to responsible product stewardship. We strive to improve the life cycle of the products we make - from the raw materials and services we procure for operations, through distribution, end use and management of product disposal. We use recycled material as much as possible in our operations but not at the expense of quality.

Energy Conservation and Efficiency Improvements

We are taking aggressive steps to conserve energy and reduce the impact of greenhouse gas (GHG) emissions arising from our operations. Our initiatives include increasing energy efficiency in our manufacturing operations, improving efficiency within our transportation fleet, investing in low carbon energy and by encouraging a lower carbon footprint within our supply chain. Summarised below are some examples of energy saved per unit of activity level on specific production lines and processes across our sectors.

- A multi-log furnace was introduced in the extrusion process at the Purification sector resulted in a 33% saving in energy consumption

- The modification of a dryer and replacement of a hot air generator at the Construction Materials sector saw an energy saving of 58%, while the replacement of blowers resulted in an 80% energy saving

- In the Agriculture sector savings were achieved by rationalising the number of staff transport cycles, while a 10% reduction was achieved in furnace oil consumption in steam boilers

- The Fibre sector used solar energy to dry approximately one tonne of wet fibre to conserve electricity on a pilot basis

- Through the installation of energy saving machinery and equipment including the replacement of high powered motors with low powered motors where applicable, introduction of capacitor banks, variable speed drives, energy saving lighting and close monitoring and controlling of energy usage at each location, the Plantations sector reduced energy usage during the year.

Water Consumption and Discharge

Safe, clean, accessible water is essential to the well-being and economic prosperity of the communities we serve, and also to the ecosystems upon which we all rely. It is also vital for our business operations. Therefore we are intensely engaged in water stewardship.

Likewise, business units ensure that water discharge meet all applicable regulatory requirements. These are monitored regularly, internally and externally.

Our Carbon Footprint

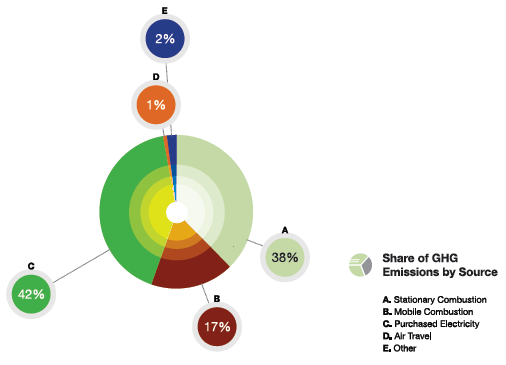

As an important aspect of measuring and managing the environmental impact of the Hayleys Group we made our first attempt at computing and reporting our greenhouse gas (GHG) emissions in FY 2011/12. This is our second voluntary disclosure, and like before, it is based on the WBCSD/WRI Greenhouse Gas Protocol Corporate Accounting and Reporting Standard (‘Corporate Standard’) and the most recent versions of applicable appendices and calculation tools.

Financial control is the basis for consolidating the GHG emissions, and the boundary is largely the same as that given under Reporting Parameters, except that not all companies are included in the carbon footprint computation due to the non-availability of data. Significant exclusions, as in the previous computation, are our Textiles sector and overseas business operations.

Hayleys and Employees Complete IT Centre Education Initiative to Northern Schools

A three-year initiative engaging the youth of Northern Sri Lanka reached successful completion, when Hayleys formally opened a newly constructed, fully equipped IT Centre at the Poonekary Maha Vidyalayam in Kilinochchi on 3rd August 2012.

This was initiated based on the need for post-conflict humanitarian assistance identified in 2009. The project has evolved into a sustainable initiative and plays an essential role in developing the youth in the North for future employment prospects.

The IT Centre is the second fully-equipped computer training centre of its kind; the first being the centre at Yogipuram Maha Vidyalam in Mullaitivu constructed in 2010. Both projects were funded by the ‘Internally Displaced Sri Lankans’ (IDSLs) Relief Fund of the Hayleys Group, established in 2009 to support humanitarian assistance initiatives. The fund comprises a day’s salary donated by employees across the Group and a similar amount contributed by the Hayleys Group.

DPL wins prestigious Asia Responsible Entrepreneurship Award for ‘Investment in People’: Firstlight™ initiative places Sri Lanka first in Southeast Asia region

Dipped Products PLC (DPL) emerged winner of the Asia Responsible Entrepreneurship Awards 2012 for Southeast Asia, in the ‘Investment in People’ Category.

DPL clinched the Category Award for championing sustainable and responsible entrepreneurship through its Firstlight™ project, which gave the world its first ethical rubber gloves.

Firstlight™ is DPL’s home-grown sourcing initiative. Coupled with market sustainability and corporate social responsibility, it is aligned to empower smallholder rubber farmers to achieve their full potential. The Company engages all components of the value chain, from suppliers to buyers and end customers and in doing so, encourages the move towards ethically sourced and manufactured products.

A significant change this time is that we are reporting emissions directly at Group level (but analysed by sectors) and not by individual companies like last time. This makes a difference in the assignment of Scopes for purchased electricity, although the consolidated total is unaffected. This approach simplifies data collection and minimises possible double counting when consolidating at Group level.

Subject to the above, our reporting under Scopes 1 and 2 is complete except for fugitive emissions from refrigeration and air conditioning plants, due to the difficulty in obtaining data in respect of some reporting entities. Reporting under Scope 3, which is optional, is selective. As before we are reporting on three significant sources here, namely, combustion and purchased electricity consumed in assets/premises not financially controlled by the Group, and employee air travel on business. GHG emissions arising from air travel were computed individually for each leg of journey taking into account distance, type of flight and class of seating.

Carbon Footprint (Tonnes CO2 Equivalent)

| Sector | Stationary Combustion | Mobile Combustion | Purchased Electricity | Air Travel | Purchased Electricity | Other | Total GHG Emissions by Sector | Share of GHG Emissions by Sector, % |

| Manufacturing | ||||||||

| Fibre | 59.9 | 61.8 | 1,161.8 | 11.3 | – | – | 1,294.8 | 2.4 |

| Hand Protection | 8,749.6 | – | 5,722.5 | 100.3 | – | – | 14,572.4 | 26.6 |

| Purification | 7,320.0 | 372.2 | 3,704.8 | 94.9 | – | 8.7 | 11,500.6 | 21.0 |

| Construction Materials | 2,620.1 | 107.8 | 2,286.8 | 13.8 | – | 72.0 | 5,100.5 | 9.3 |

| Agriculture | ||||||||

| Agriculture | 874.0 | 67.7 | 672.7 | 89.8 | – | – | 1,704.2 | 3.1 |

| Plantations | 281.6 | 1,894.0 | 6,681.8 | 17.1 | – | 245.6 | 9,120.0 | 16.6 |

| Services | ||||||||

| Transportation and Logistics | – | 6,952.0 | 900.4 | 79.1 | 45.5 | 154.2 | 8,131.1 | 14.8 |

| Consumer Products | – | – | 62.1 | 31.9 | – | 446.4 | 540.4 | 1.0 |

| Leisure and Aviation | 820.1 | 84.8 | 1,269.9 | 12.7 | – | – | 2,187.5 | 4.0 |

| Power and Energy | – | 13.0 | 74.2 | 12.5 | – | 96.1 | 195.8 | 0.4 |

| Investments and Services | – | – | 57.7 | 2.8 | – | – | 60.5 | 0.1 |

| Holding Company | 10.5 | – | 356.6 | 8.1 | – | – | 375.2 | 0.7 |

| Total GHG emissions by source | 20,735.8 | 9,553.3 | 22,951.3 | 474.3 | 45.5 | 1,023.0 | 54,782.8 | 100 |

| Share of GHG emissions by Source, % |

37.9 | 17.4 | 41.9 | 0.9 | 0.1 | 1.9 | 100 |

Subject to the above, the total GHG emissions (carbon footprint) of the Hayleys Group during FY 2012/13 amounted to 54,783 tonnes carbon dioxide equivalent (tCO2e), which is marginally higher than the 54,014 tCO2e reported in the previous year. Notwithstanding possible distortions arising from changes within the GHG boundary and omissions in data collection, it implies that the GHG emissions intensity has reduced significantly when related to an activity level, such as the Group turnover, which increased 13% YoY.

Direct GHG emissions arising from combustion (Scope 1) accounted for the largest share at 55% of the total, with stationary combustion taking a 38% share, reflecting the Group’s large manufacturing base. Indirect GHG emissions from purchased electricity (Scope 2) followed closely with a 42% share.

The manufacturing sector, which contributed 51% to Group turnover, accounted for 59% of total GHG emissions, with Hand Protection (DPL Group) and Purification (Haycarb Group) accounting for 27% and 21% of the overall total. They are both large and successful manufacturing groups serving global markets which contributed 39% and 26% respectively to the Hayleys Group turnover.

As for our next steps, we will further refine measurement procedures and aim to cover Scopes 1 and 2 in full. To improve completeness we will include the Hayleys Textiles sector and more Group companies within the GHG emissions reporting boundary. These measures will enable us to benchmark our environmental performance more consistently and accurately over time, as well as against peers. Internal target setting would then become a natural outcome, with a positive spinoff in terms of cost savings, particularly in the context of the steep electricity tariff hikes coming into force in 2013.

Initiatives to Reduce Our Carbon Footprint

As a result of measures adopted to reduce GHG emissions, the Purification sector sold 7,232 carbon credits during the year ended December 2012. Meanwhile, GHG emission reductions were also achieved at HJS Condiments Ltd in the Agriculture sector.

Waste by Type and Disposal Method

Waste is segregated and disposed of in compliance with applicable regulations. Details of total weight of waste by type and disposal method are given below for key business sectors.

| Sector | Type of Waste | Methods of Disposal | Amount Disposed (Tonnes) |

| Fibre | Non-hazardous waste | Land fill | 750 |

| Purification | Hazardous waste | Re-use | 6.3 |

| Non-hazardous waste | Re-use | 6,111.6 | |

| Construction Materials | Non-hazardous waste | Re-use | 1,096.6 |

| Agriculture | Hazardous waste | Incineration | 8.5 |

| Non-hazardous waste | Composting | 2.4 | |

| Transportation & Logistics | Hazardous waste | Through authorised contractors | 20 |

| Non-hazardous waste | Authorised waste disposal collector | 1.2 |

International Global Compact Participants Commend Kelani Valley Plantations’ Sustainability Initiatives

The UN Global Compact is a strategic policy initiative for businesses that are committed to aligning their operations and strategies with ten universally accepted principles in the areas of human rights, labour, environment and anti-corruption. Kelani Valley Plantations (KVPL) PLC sought to display their voluntary corporate citizenship initiatives to the seven representatives of Local Networks (LN’s).

As part of the four-day Local Network Exchange Programme held in November 2012, seven Global Compact participants from countries spanning the United States, Egypt, Indonesia, Bangladesh and India visited Kelani Valley Plantations’ rubber and tea estates in Dewalakanda and Panawatte. The Exchange Programme sought to foster collaboration among Local Networks by providing an opportunity to share experiences and identify best practices across regional boundaries.

All delegates encouraged and commended the good practices of CSR in KVPL. They commended the efforts initiated to strengthen employer - employee relationships and their wellbeing which in the long-run will create a happy workforce and enhance labour productivity. KVPL’s community initiatives, and high sanitation and hygiene standards at factory and estate level received high approval from the delegates. Overall KVPL was recognised as a role model for responsible business.

Compliance with Environmental Laws and Regulations

Hayleys Group Legal unit has not been informed of or has pursued any action where any fines were imposed in relation to non-compliance with laws and regulations related to environmental matters.