Sector Reviews

Textiles

Business Domain

The Hayleys Textile Sector manufactures weft knitted fabrics for the export-driven apparel industry. The world's leading apparel brands such as Decathlon, George/Asda, Marks & Spencer, NEXT, Tesco, Intimissimi are the key end customers. Sri Lanka imports about 50% of its knitted fabric requirements, with the balance supplied by four major domestic manufacturers, with Hayleys MGT having the potential to meet 25% of this capacity together with a wider product range which includes Polyester, Fabric Printing and Fabric Brushing.

Key Performance Indicators

| Indicator | Measure | Unit | FYE 31st March | ||

| 2013 | 2012 | 2011 | |||

| Growth | Revenue | USD ’000 | 44,193 | 45,936 | 58,322 |

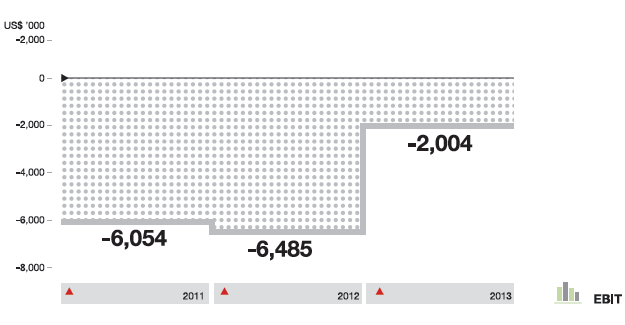

| Earnings Before Interest and Tax | USD ’000 | (2,004) | (6,485) | (6,054) | |

| Profit After Tax | USD ’000 | (3,495) | (7,582) | (7,079) | |

| Assets (Avg) | USD ’000 | 36,230 | 38,936 | 46,218 | |

| Capital Employed | USD ’000 | 24,900 | 28,723 | 39,517 | |

| Profitability | Return on Average Capital Employed* | % | -14 | -26 | -18 |

| Liquidity | Current Ratio | Times | 0.55 | 0.48 | 0.73 |

| Stability | Gearing | % | 51 | 70 | 60 |

| Asset utilisation | Asset Turnover Ratio | Times | 1.23 | 1.19 | 1.25 |

| Productivity | Ebit per Employee | USD ’000 | (2.33) | (7.09) | (6.60) |

* Excluding Real Estate

Operations

The Hayleys Textile Sector is primarily engaged in weft knitting, dyeing and finishing of cotton, cotton blends and polyester fabric. These are produced using some of the best brands in knitting, dyeing and finishing machinery to ensure the quality standards required by our customers. The capability of additional finishes such as the chemical treatment of fabric, fabric brushing, fabric printing gives the customers added flexibility.

Internally, the Sector completed a major reorganisation and turnaround programme during the year under review to return to profitability in 2014. Implementation of an ERP solution to improve productivity, financial controls, production planning and inventory management through SAP, and new raw material supply routes for dyes, chemicals and yarn were developed to meet the ever increasing challenge of price pressure. Additional technical support was brought in to improve dyeing and finishing so as to improve our service levels to the customer. These changes have made significant improvements in the Dyeing and Finishing RFT (Right First Time) to reach new heights at 94% and 96% respectively. This has resulted in a reduction is waste, reduction in reprocessing costs, improving quality levels and the improvement of On Time Delivery (OTD).

The key challenges from the external environment were the cost increases in yarn which exceeded global predictions, and customer resistance in accepting corresponding price increases on finished fabric. Energy cost increase was another major area of concern. Action has been taken to mitigate these impacts with cost saving initiatives.

Our competitive advantage stems from being in a position to carry out additional fabric finishes such as brushing to make fleece fabric and fabric printing, our large capacity to produce collars and cuffs, and our high-tech dyeing machines to maintain consistency in colour. To exploit these advantages we are looking at increasing market share through improved delivery times, competitive pricing and superior quality, and also broaden our product portfolio by targeting some high value products.

Strategies in Action

Hayleys MGT has focused on some of the key areas to improve the overall performance of the Company. Planning at the point of order in-take to the point of delivery with raw material requirement planning being a key area of focus. This will reduce waste, control inventory and improve OTD. Therefore the resources and the technical expertise in the Planning division has been further strengthened. Additional technical know how on the ERP system has been brought in to improve the effectiveness of SAP usage and thereby improving the throughput. Raw material usage and its cost controls through SAP is another area that is currently being strengthened.

Customer focus with a high degree of service levels, value addition propositions are being discussed to work closely with our customers with a long-term partnership through business development being another area of focus. People motivation is the greatest area of focus by creating awareness of the business needs, global changes, competition and customer requirements. Best practices and policies are being implemented to improve the throughput and thereby increasing productivity.

Outlook

Hayleys Textiles is poised to turnaround during the Financial year 2013/14 by taking on the increased challenges of price pressure from customers, improve its capacity fulfilment, reduce wastage and costs, improve profitability, improve labour relations and increase overall people motivational levels.